Maximise the Deposition Process with NX CAM

As the additive manufacturing industry has matured, more hardware manufacturers are beginning to marry robots with additive manufacturing. This alleviates the need for support structures and also widens the working envelope for the technology allowing for much larger parts to be produced. Siemens is working with the best in the industry and our multi-axis deposition path generation software is being used to drive many of these cutting-edge machines.

The NX Cam allows you to utilize the degrees of freedom of the additive machine to reduce the need for support & maximize the deposition process.

This gives multiple benefits, including:

-

giving you one fully integrated system

-

no need to build complex support structures

-

Additive path planning for robot and machine tools

-

Flexible 5 Axis Additive Platform

Why NX AM Multi-Axis?

Driving multi-axis additive hardware takes special software. Normal planar 3D-print products cannot generate the complex 3D deposition paths required for multi-axis 3D printing. This is where the NX Additive Manufacturing (AM) Multi-Axis solution is key.

Create complex, 3D deposition paths

Drive complex deposition paths for multi-axis hardware using a combination of proven pre-programmed deposition paths, like helixes. Also use the software for advanced path planning for activities like cladding. These complex motion paths are almost impossible to generate accurately using other tools.

Access advanced AM path planning, validation and manufacturing preparation tools such as:

-

A complete CAD tool set for feature decomposition, stage modeling and fixture design to setup jobs in your machine’s kinematic environment

-

Comprehensive simultaneous 5-axis AM path planning for robots and machine tools, supporting a wide range of tool path operations

-

A powerful system to combine multi-axis deposition and subtractive manufacturing

operations in the same tool path setup -

A simulation system to validate your multi-axis AM machining setup and analyze its performance via a production digital twin

-

Highly productive, modular CNC automation systems controlling up to 93 axes in 30 machining channels

.png)

Industrialized additive manufacturing doesn't end with printing

NX provides a suite of necessary solutions for the processing of printed parts including machining and post-print inspection. Having these solutions integrated with capabilities for design and additive manufacturing means that the entire 3D printing process from beginning to end can be handled within a single system.

From depowdering, to support removal, to quality inspection, Siemens has the solution.

CNC Programming

The proven, integrated tools in NX CAM allow operators to easily perform post-print processing. Having both additive and subtractive functions in a single software package means the AM process can flow smoothly from printing to post-print processing. Operators can easily take near net shape parts to their final shape and finish, automate the removal of the part from the build tray, automate the removal of supports, and perform other post-print operations with NX CAM.

Industrialized additive manufacturing doesn't end with printing...

NX provides a suite of necessary solutions for the processing of printed parts including machining and post-print inspection. Having these solutions integrated with capabilities for design and additive manufacturing means that the entire 3D printing process from beginning to end can be handled within a single system.

From depowdering, to support removal, to quality inspection, Siemens has the solution.

CNC Programming

The proven, integrated tools in NX CAM allow operators to easily perform post-print processing. Having both additive and subtractive functions in a single software package means the AM process can flow smoothly from printing to post-print processing. Operators can easily take near net shape parts to their final shape and finish, automate the removal of the part from the build tray, automate the removal of supports, and perform other post-print operations with NX CAM.

Depowdering

One unique aspect of the additive manufacturing process is the need for powder removal when using powder-based additive processes. Siemens has partnered with Solukon on a unique automated depowdering solution that uses knowledge of the part geometry to drive the Solukon depowdering system. With a combination of multi-axis manipulation and key frequency vibration, the system loosens packed powder and facilitates the ejection of powder from internal channels, vastly reducing the time necessary for this post-process activity.

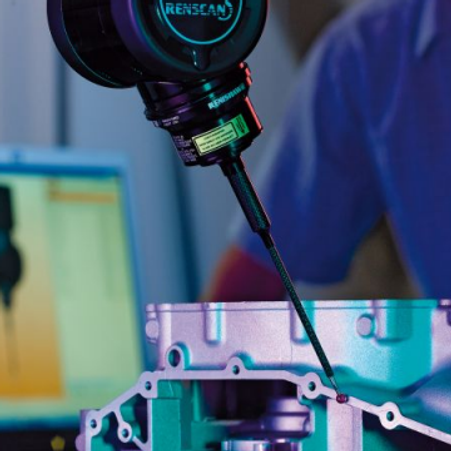

Quality Inspection

NX has a wide range of integrated inspection and validation tools that can be used as the final stage in a complete additive manufacturing workflow. From the programming of CMM tools to geometry comparison functions used with scan data, NX can handle all the post-print inspection necessary to validate the final quality of printed parts.