Unleash your innovation with the next generation of design, simulation, and manufacturing solutions

Scalable NX CAD/CAM

Building on its legacy of best-in-class customer deployment readiness and data preservation, Siemens NX delivers the next generation of design, simulation and manufacturing solutions that enable companies to realise the value of the digital twin in the end-to-end process. Unleash your innovation with the only open and integrated multidisciplinary platform.

Help your teams collaborate more effectively and deliver innovative, high-quality products faster—with unparalleled precision.

The NX CAD/CAM advantage

20%

Shorter time to delivery

Meet tight deadlines with NX integrated design and manufacturing capabilities.

Why Siemens NX?

Siemens NX software is a flexible and powerful integrated solution that helps you deliver better products faster and more efficiently. NX delivers the next generation of design, simulation, and manufacturing solutions that enable companies to realize the value of the digital twin.

Supporting every aspect of product development, from concept design through engineering and manufacturing, NX gives you an integrated toolset that coordinates disciplines, preserves data integrity and design intent, and streamlines the entire process.

NX For Design (CAD)

NX for Design enables you to deliver products “right to market, first time" using more virtual product models and fewer, more costly, physical prototypes. This leads to market gains, lower development costs, and improved product quality.

NX For Manufacturing (CAM)

Program CNC machine tools, control robotic cells, drive 3D printers and monitor quality using one software system.

NX Line Designer

Design assembly lines, equipment and tool requirements in a 3D environment. Optimize factory space and maximize capital resource utilization by digitally configuring factory layouts.

NX MCD

Mechatronics Concept Designer provides an end-to-end solution that enables multidiscipline collaboration, reuse of knowledge and reduced time to market.

Before the adoption of NX, our development cycle took 12 to 14 months; with NX, we’ve reduced our development cycle to six to eight months. This is a significant result, not just because costs have been cut proportionally, but mostly because the capacity of our product development department has increased to such an extent that we can create an additional model each year.

Matteo Tenni, Product Engineer, MET

Digital Manufacturing Centre (DMC) - Empowering Innovation through NX with Kaizen PLM

Kaizen PLM worked closely with the Digital Manufacturing Centre (DMC) to implement Siemens NX™ as part of their end-to-end additive manufacturing solution. Through this partnership, DMC has been able to optimise production workflows, reduce part weight, and deliver exceptional results to customers across sectors—from motorsport to medical.

Industry: Aerospace, Automotive, Marine, Medical

Software: Siemens NX

End-to-End Digital Manufacturing of Femoral Implants with Kaizen PLM, Seco Tools, and Additure/Nikon SLM Solutions

Kaizen PLM, a leader in additive manufacturing and medical device solutions, collaborated with Seco Tools and Additure/Nikon SLM Solutions to develop a cutting-edge, end-to-end digital manufacturing strategy for femoral implants. By leveraging Siemens NX CAM and Simcenter 3D, Kaizen streamlined the entire workflow from design to CNC machining, additive manufacturing, and simulation, demonstrating a fully integrated and efficient process.

Watch more about Siemens NX

Siemens NX

Siemens NX

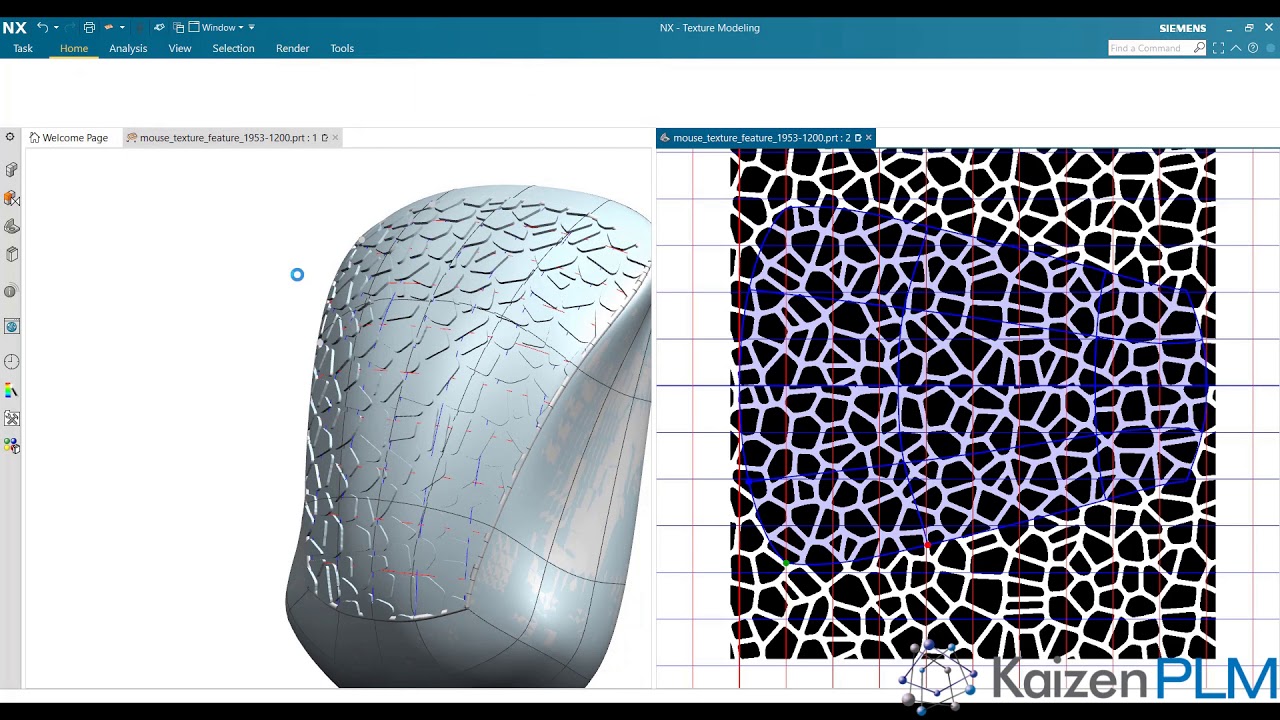

NX Mouse Texture Modeling

NX Algorithmic Modelling

NX AM - Patient Specific Printed Components