What’s new in Simcenter Systems Simulation 2511?

- Mikala O'Connor

.png/v1/fill/w_320,h_320/file.jpg)

- Dec 11, 2025

- 10 min read

Simcenter Systems Simulation 2511 has been released, introducing new capabilities that accelerate innovation across industries such as automotive, aerospace, heavy equipment, and turbomachinery.

This latest version empowers engineers with smarter modeling workflows, AI-based documentation assistance, and enhanced productivity in Simcenter Amesim, Simcenter Flomaster, and Simcenter System Analyst. Together, these updates help users work faster, manage greater complexity, and seamlessly integrate simulation throughout the product development lifecycle.

Simcenter X

This release reinforces Simcenter Systems as a key pillar of Siemens’ digital transformation strategy, with continued focus on cloud enablement, AI-driven assistance, and user productivity across system simulation workflows.

Simcenter X Advanced – Cloud-managed desktop

Simcenter X Advanced offers a secure, cloud-managed desktop that enables users to access Simcenter Amesim without the burden of license setup and management. This deployment option simplifies IT administration, accelerates onboarding, and scales efficiently across distributed engineering teams.

Simcenter X AI Chat Assistant – Instant answers, built into the cloud environment

For customers using Simcenter X Advanced, the integrated AI chat assistant delivers contextual answers with direct links to documentation.

Supporting multiple languages helps teams find information faster, streamline troubleshooting, and remain productive across global simulation environments.

Simcenter Systems 2511

The Simcenter Systems 2511 release strengthens the portfolio with key improvements in electrification, cloud accessibility, and user experience.

Engineers benefit from enhanced modeling accuracy, faster setup, and improved visualization features that support system-level design across industries. From streamlined parameter management to more efficient simulation workflows, Simcenter Systems 2511 empowers users to innovate with greater speed and confidence.

Electrification remains a driving force in the Simcenter Systems portfolio, and this release continues to expand capabilities for battery modeling, integration, and optimization. With Simcenter Amesim 2511, engineers can now design and validate battery packs more efficiently, leveraging improved workflows for parameter import and thermal management. These innovations support electric vehicle (EV) and energy storage applications, helping teams accelerate the transition toward sustainable and high-performance electrified systems.

Battery

Battery pack assistant – Seamless electrical parameter integration

Defining accurate battery cell parameters can often be tedious and prone to error. With Simcenter Amesim 2511, part of the Simcenter Systems Simulation portfolio , battery designers and integration teams can now automatically import cell electrical parameters directly from a validated database or an existing model into the battery pack assistant.

This new capability streamlines the setup process, ensuring that simulations start from trusted data while minimizing manual input errors. Engineers can reuse existing models, resize them efficiently to match target capacity, and evaluate pack architectures earlier in the design cycle, all within a unified battery design environment.

Whether applied to EV battery modeling or stationary energy storage systems, this update accelerates pack design and improves accuracy.

Battery pack assistant – Capture heat gradients where they matter most

Controlling temperature gradients within a battery pack is crucial for ensuring safety, optimal performance, and extended durability. In Simcenter Amesim 2511, the battery pack assistant introduces a new capability that allows users to thermally discretize pattern groupings in any direction (X, Y, or Z) to better capture critical heat variations across packs.

This flexible approach enables engineers to model a wide range of cell technologies, from prismatic to blade cells, adapting the size and orientation of thermal discretization to each design’s unique behavior. With just one click, users can generate detailed thermal models that accurately reflect real-world gradients, ensuring accurate simulation results.

For battery designers and integration teams working in the automotive, mechanical, or energy storage sectors, this enhancement provides the control needed to refine thermal management strategies and improve the accuracy of electrification simulation workflows.

Chassis engineering

Electric motorcycle demo model – Analyze ride and handling with ease

Designing an electrified motorcycle chassis that strikes a balance between ride and handling performance can be a complex process. With Simcenter Amesim 2511, engineers now have access to a new electric motorcycle demo model, built using the 3D mechanical library and integrated with vehicle dynamics driver models.

This demo serves as a fully modular starting point for creating and analyzing electrified motorbike architecture. Users can quickly explore different layouts and optimize the position of heavy components, such as the battery pack and e-motors, to ensure stability and control across varying speeds and trajectories.

The real-time capable model helps motorbike manufacturers and suppliers study ride and handling dynamics in curves, evaluate design trade-offs, and accelerate development from concept to validation.

Ground designer – Create a batch from parameters

Testing vehicle behavior across different roads and terrain conditions is crucial for accurate chassis engineering. In Simcenter Amesim 2511, the new ground designer batch feature introduces the ability to generate virtual proving grounds with multiple obstacle heights, shapes, and spacing, all defined through customizable parameters.

This update enables engineers to create batch runs directly from any parameter in the ground designer, allowing for quick exploration of numerous test scenarios and geometries. The result: faster analysis cycles and deeper insights into vehicle dynamics performance on parametric 3D proving grounds.

With this capability, automotive, off-road, and heavy equipment engineers can easily optimize suspension, stability, and control systems under varied conditions, boosting the efficiency and realism of vehicle simulation workflows.

E-motors

Squirrel Cage Induction Machine (SCIM) – Enhanced electro-thermal modeling

Designing high-power-density electric drivetrains requires a precise understanding of thermal behavior and magnetic effects. The enhanced squirrel cage induction machine (SCIM) model in Simcenter Amesim 2511 introduces detailed loss definitions and non-linear inductance support for accurate electro-thermal simulations.

This update enables engineers to analyze temperature-dependent losses that directly impact e-powertrain performance, helping to refine thermal management strategies and enhance system reliability. Through comprehensive modeling of DC, AC, and iron losses, the new SCIM component supports more accurate sizing, efficiency predictions, and component optimization.

Whether used in automotive, aerospace, or industrial applications, this upgrade empowers powertrain engineers to push performance limits with greater confidence and precision.

Energy and thermal management

Efficient thermal management is crucial for maintaining performance and safety in electrified systems. In Simcenter Amesim 2511, new capabilities within the Heat Exchanger Assistant simplify model generation and provide early design insights to help engineers optimize HVAC and cooling systems faster.

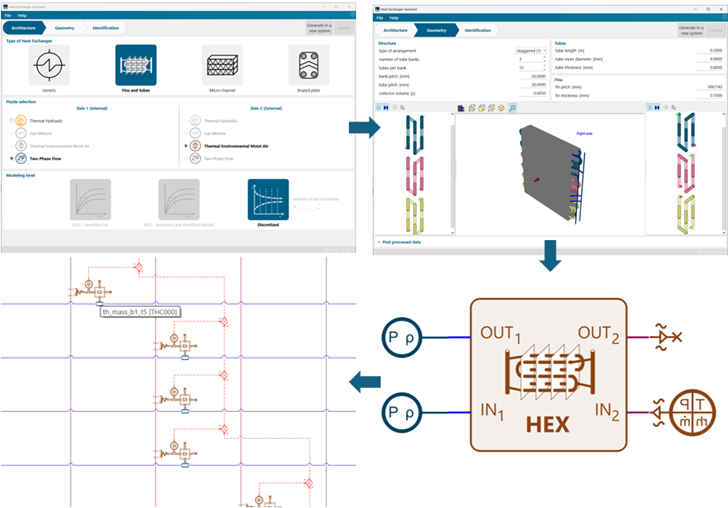

Heat exchanger assistant – Streamline your HVAC heat exchanger design

Creating detailed heat exchanger models can be time-consuming and prone to errors. In Simcenter Amesim 2511, the heat exchanger assistant receives a significant enhancement with new capabilities that expand the range of supported geometries, including fin-and-tube and multi-core micro-channel heat exchangers. Engineers can now generate complete parameterized models with integrated 2D/3D visualization more efficiently.

The updated assistant also introduces automatic sketch generation for multi-core micro-channel designs, helping HVAC and thermal engineers iterate faster and maintain consistent model structures. By simplifying model creation and providing real-time geometric feedback, this enhancement accelerates early-phase heat exchanger design and improves modeling confidence.

Heat exchanger assistant – Early heat exchanger size and mass assessment

Late-stage adjustments to heat exchanger dimensions or weight can lead to costly redesigns and delays. With Simcenter Amesim 2511, engineers can now evaluate the size and mass of heat exchangers directly in the geometry definition phase, using the heat exchanger assistant.

This enhancement provides real-time insights into packaging feasibility and component weight before running simulations, allowing teams to validate designs against system requirements earlier in the process. By integrating mass and dimensional data at the geometry stage, thermal engineers can make data-driven decisions faster and ensure alignment with performance targets and packaging constraints.

Hydrogen

Hydrogen continues to play a pivotal role in enabling clean propulsion and sustainable energy systems. With Simcenter Amesim 2511, engineers gain new modeling tools that simplify the design and integration of fuel cell and cryogenic storage systems, helping industries such as aerospace, marine, and automotive explore the future of zero-emission powertrains.

Fuel-cell turboprop demonstrator – Integrated gas, liquid, and hydrogen modeling

Designing and validating an aircraft fuel-cell system requires accurate modeling of gas, liquid, and cryogenic hydrogen interactions across multiple components. The updated fuel-cell turboprop demonstrator in Simcenter Amesim 2511 provides a ready-to-use model that shows how to configure the required fluid species and phases using the common framework shared by the gas and fluid storage libraries.

This demonstration gives engineers practical insight into cryogenic tank behavior, Boil-off gas (BOG) management, and fuel-cell operation throughout an entire flight cycle. It highlights how individual subsystems such as the cryogenic storage system, the fuel cell stack, and associated balance-of-plant (BoP) components interact within a complete aircraft configuration.

Simcenter Amesim 2511 also introduces an improved hydrogen aging model, enabling engineers to evaluate long-term performance decay and its impact on power output, efficiency, and mission range. Together, these enhancements accelerate system-level validation and reduce setup time for hydrogen-powered aircraft studies.

Beyond electrification and hydrogen innovation, Simcenter Systems Simulation 2511 also strengthens its foundation with improvements that enhance accuracy, interoperability, and productivity across the modeling environment. These updates help engineers build, manage, and analyze system models more efficiently, whether they’re optimizing pneumatic and gas systems, working with advanced libraries, or improving collaboration through tighter version control.

With new capabilities across both Simcenter Amesim and Simcenter Flomaster, including enhanced simulation libraries, improvements to turbomachinery modeling, and strengthened Git integration, Simcenter Systems Simulation 2511 reinforces the robustness and scalability of the platform for all industries.

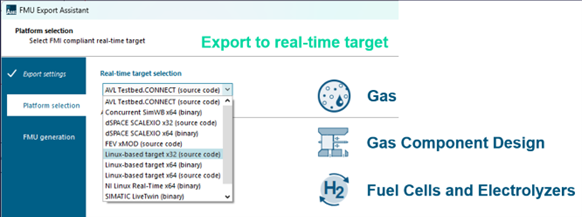

Gas library – Build scalable and accurate gas systems

Modern gas systems require precise control, reliable modeling, and strong scalability, especially in automotive, aerospace, and industrial applications. The new gas library in Simcenter Amesim 2511 introduces a unified, real-time-capable framework that replaces multiple legacy pneumatic and gas libraries, offering greater accuracy, consistency, and flexibility.

This next-generation library integrates industry-standard modeling capabilities, including ISO-6358 compliant components and Redlich–Kwong–Soave (RKS) equations of state, enabling engineers to simulate compressible flows and advanced gas behavior with improved fidelity. The library is also fully compatible with real-time export, making it suitable for hardware-in-the-loop (HiL) applications and control system validation.

By consolidating and modernizing the modeling workflow for gas systems, the new gas library helps teams build, maintain, and scale large multi-domain system models more efficiently and with higher reliability.

New help system – Faster access to smarter documentation

Accessing technical documentation efficiently is critical for simulation engineers. The new browser-based help system in Simcenter Amesim 2511 delivers a modernized and more intuitive documentation experience.

With enhanced search capabilities, familiar navigation categories, and integrated web features such as zoom, bookmarks, translation, and history, users can now find information more quickly and easily. The new help platform also offers seamless integration with Simcenter Amesim, allowing engineers to directly access relevant documentation without interrupting their workflow.

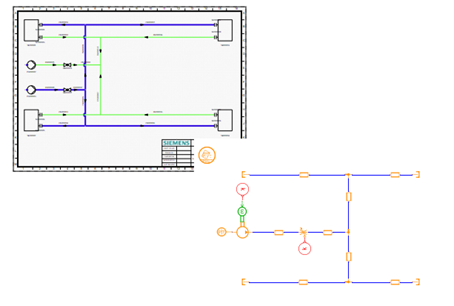

NX Diagramming XML import – Simplify system model creation

For fluid system engineers working on complex piping networks, CAD tools are often used to define the initial layout of 2D diagrams. However, transferring these definitions manually into a system simulation environment can be time-consuming and error-prone.

The new NX Diagramming XML import capability in Simcenter Amesim 2511 bridges this gap by allowing users to automatically generate system models directly from NX Diagramming files.

This functionality enables engineers to rapidly create 2D piping network definitions inside Simcenter Amesim, ensuring seamless interoperability between CAD tools and system simulation. By eliminating repetitive manual work, it accelerates model setup and provides a smoother transition from early design to performance validation, benefiting industries such as energy, oil and gas, marine, aerospace, and process engineering.

3D Scenes – Enhanced visualization for model setup and analysis

Understanding model behavior visually can dramatically improve accuracy and productivity. The new 3D Scenes tool in Simcenter Amesim 2511 introduces an advanced 3D visualization environment that enables engineers to interact directly with simulation models, whether it be during building or in the simulation phase.

This enhancement enables users to set parameters effortlessly by interacting with 3D objects, gain a better understanding of the system before running simulations, and interpret physical quantities through clear visual cues. With two distinct 3D viewing modes available, engineers can visualize model states before and after simulation, enabling them to validate configurations and identify potential modeling issues early.

By providing intuitive visualization and interactive parameter control, the new 3D Scenes feature empowers system simulation engineers across industries to make faster, more informed design decisions.

Test Execution Manager – Compare reports side by side

As simulation models evolve, engineers often need to validate changes, compare results across versions, or assess the impact of updates to libraries and model parameters. Manually comparing outputs from different runs can be tedious and error-prone, especially when handling large datasets or complex systems.

The enhanced compare-report feature in the Test Execution Manager streamlines this process by displaying two reports side by side in a clear, structured table. Differences in parameter values, simulation outputs, and timeseries data are automatically highlighted, making it easier to pinpoint what changed between two executions.

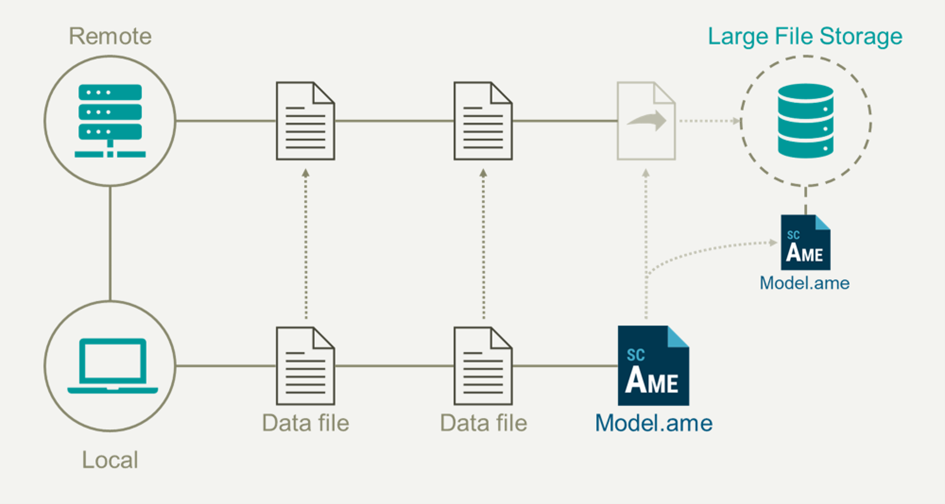

Client for Git – Large File Storage (LFS)

The Large File Storage capability in Simcenter Client for Git keeps repositories lightweight by storing large files in a dedicated area.

This speeds up uploads, removes file-size limits, and enhances version control efficiency.

This capability improves productivity by reducing the manual effort required for regression testing and model validation. It also strengthens traceability and transparency across simulation runs, helping engineers understand the impact of updates more quickly and make better-informed decisions.

Client for Git – Delete branches from server collections

As simulation projects evolve, Git collections often accumulate numerous branches — many of which eventually become outdated or unused. These obsolete branches take up server space, clutter the project history, and make it harder for teams to navigate active development lines.

With Simcenter Client for Git in the 2511 release, users can now delete branches directly from server collections. This capability makes it easier to remove unnecessary or obsolete branches at the source, helping teams keep their repositories lean and better organized.

By decluttering the repository, server collections become smaller and more efficient, improving performance during repository operations. It also supports better project hygiene by maintaining a cleaner and more understandable version history.

Overall, this enhancement enables engineering teams to manage their branches more effectively and maintain a streamlined, professional version-control workflow.

Turbomachinery simulation improvements

Meeting today’s efficiency and performance targets in turbomachinery requires highly detailed and integrated modeling capabilities. As systems grow more complex, traditional approaches often struggle to capture the full dynamics of rotating components, secondary air flows, and co-simulation behaviors across tools.

Simcenter Flomaster 2511 introduces several targeted enhancements to address these challenges. Internal duct and forced vortex components have been upgraded to support turbine speed data directly, enabling more realistic and precise modeling of rotating secondary air systems. A new flow-tracking capability now enables engineers to visually trace which inlet sources contribute to the flow at any given outlet, providing deeper insight into system behavior and helping to accelerate diagnostics. Additionally, FMU export has been reinforced with support for implicit iterations and improved error handling, resulting in more robust co-simulation with Simcenter 3D Thermal.

Together, these improvements deliver more accurate turbine speed modeling, clearer flow-origin identification, and smoother integration into whole-engine digital workflows, supporting faster decisions and more reliable development of high-efficiency turbomachinery systems.

Get in touch with the team at Kaizen PLM to learn more about Simcenter Systems Simulation 2511 and how it could support your business.

Comments